The Difference between Centrifugal Compressors and Other Rotating Equipment

Centrifugal compressors are unique compared to most other rotating equipment. This uniqueness brings with it complexities that other rotating equipment does not have and is easy to underestimate.

What is the Secret to a Great Compressor Selection?

For many oil and gas fields, installing compression is a vital step necessary for enhancing future revenues. Many oil and energy companies are faced with the challenge of overcoming declining field pressures. An optimized gas compression system is required but there is a secret to it.

Let's Face it, Condition Monitoring of Rotating Equipment is never Enough

The benefits of standard condition monitoring approaches are established and well known but is this methodology enough for the standards of operational excellence expected of oil and gas assets today? Even in previous, more traditional.

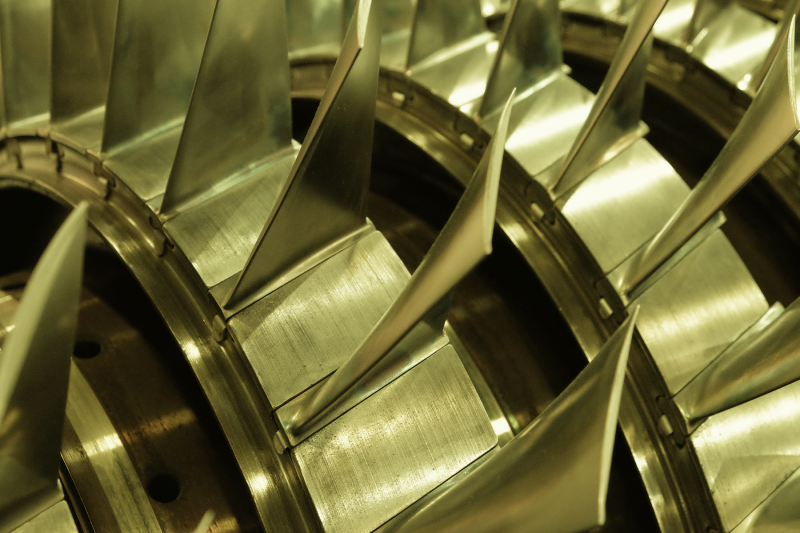

![Performance and Mechanical Running Tests of Centrifugal Compressors I [Best from the web]](https://images.squarespace-cdn.com/content/v1/61cd6f74eb12844d9b61d10a/1645702577542-BHHC644F6FZZUMN2IS32/Performance+and+Mechanical+Running+Tests+of+Centrifugal+Compressors+I+%5BBest+from+the+web%5D.png)

Performance and Mechanical Running Tests of Centrifugal Compressors I [Best from the web]

Usually, contractors and users include performance tests in the base scope of the purchased compressor. However, during bid conditioning, the Engineers tend to give less attention to the evaluated bidders’ shop test capabilities. Frequently this significant parameter is not assessed until after receipt of the compressor manufacturer’s test procedure.

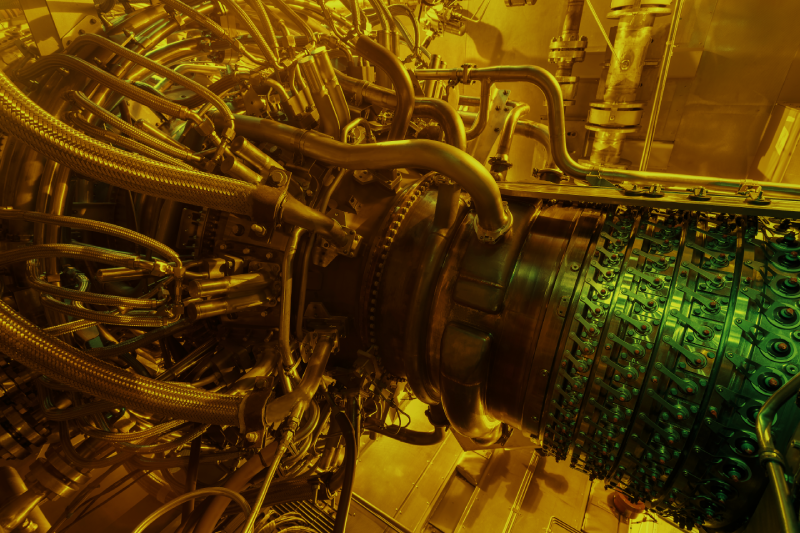

![Tips for witness testing [Best from the web]](https://images.squarespace-cdn.com/content/v1/61cd6f74eb12844d9b61d10a/1645697691456-KQGRH0QLCUI0U0HFTGKD/AdobeStock_332872460.png)

Tips for witness testing [Best from the web]

Have you been handed some responsibilities to oversee or witness a shop test for rotating equipment? If you have, then this article is for you.

Benefits of Tackling Suboptimal Performance of Centrifugal Compressors

Although the suboptimal performance of centrifugal compressors can cause serious damage to oil and gas production operations, there tends to be slowness or hesitancy to proactively act to resolve performance issues. This is especially the case if the poor…

How to Reduce Project Costs via Conceptual and Pre-FEED Studies

...one of the most effective ways to reduce overall project capital expenditure is by ensuring a rigorous, quality, and expertly executed project front-end loading. This will include all the front-end pre-planning and studies such as feasibility/appraisal and conceptual selection studies.

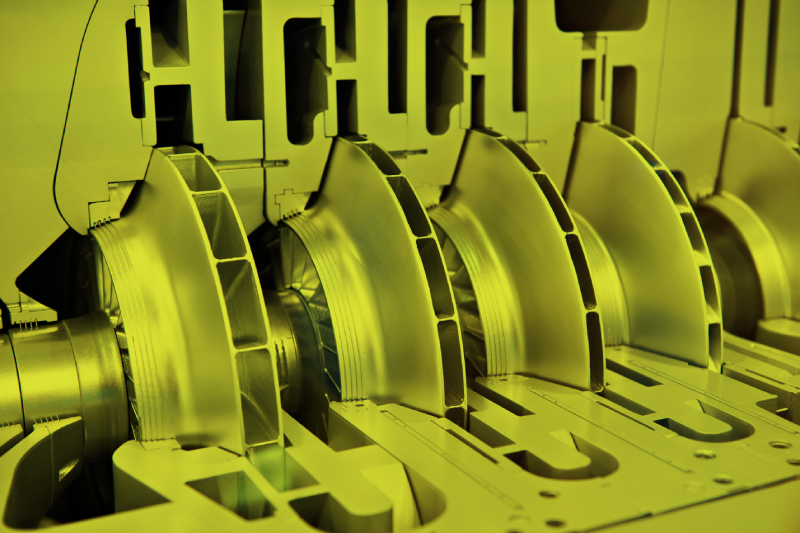

![Compressor Mapper 1.0 [Software Review]](https://images.squarespace-cdn.com/content/v1/61cd6f74eb12844d9b61d10a/1645697033997-J2OHL7MCNDNRG902D09M/multistage+compressor+%281%29.png)

Compressor Mapper 1.0 [Software Review]

Compressor Mapper is a simple but effective utility software application that converts scanned centrifugal compressor head and efficiency map images into a digitized set. This article highlights Eta Energy Solutions’ key findings and opinions following an independent review of the software.

Why Compressors are Affected by More Than What Goes on Between its Nozzles

From consulting with various oil and gas companies internationally, I have come across two common misconceptions some colleagues have..

How to Handle Excessive Centrifugal Compressor Recycling Part 2

Centrifugal compressors are however not meant to operate continuously in recycling as a normal operating regime. If this is this case, this means there is a problem that needs addressing due to its significant impact on overall production efficiency. In order to resolve the problem, one has to first understand the likely causes.

How to Handle Excessive Centrifugal Compressor Recycling Part 1

How centrifugal compressor wheels, anti-surge control system adjustments, & other turbomachinery & process modifications can reduce excessive recycling.

Why Integrated Asset Modelling is the Best Thing since Sliced Bread

For some of us who would have been drawn to this topic, integrated asset modeling will need no introduction. For the benefit of the rest of us, integrated asset modeling or integrated production modeling as it is also sometimes called is the seamless, simultaneous, and interactive modeling of all elements of an oil and gas production system.

7 Steps to Resolve Suboptimal Performance of Centrifugal Compressors - Part 2

Last week in Part 1, we explored the first three out of the seven steps which I recommend to resolve the suboptimal performance of centrifugal compressors in oil and gas service. This week, in Part 2 we look at the remaining four of the seven steps. They are as follows:

7 Steps to Resolve Suboptimal Performance of Centrifugal Compressors - Part 1

Having previously described the causes and effects of suboptimal operation of centrifugal compressors deployed in oil and gas applications, I thought it would be great this week to begin to look at some key steps we can take towards resolving the issues previously highlighted.

How Suboptimal Performance of Centrifugal Compressors causes Damage

The reality is that the suboptimal performance of centrifugal compressors can eventually have some frustrating, expensive, and potentially devastating effects. Here are some of the most frequent ones I have come across in my work.

Why Your Gas Compression Equipment May No Longer be Optimum

Gas compression equipment used in oil and gas applications may be required to operate away from their design duties in the course of the life of the field. Usually, such centrifugal compressors are meticulously designed and optimized for their initial duty.